DIGITAL DESIGN + INNOVATION

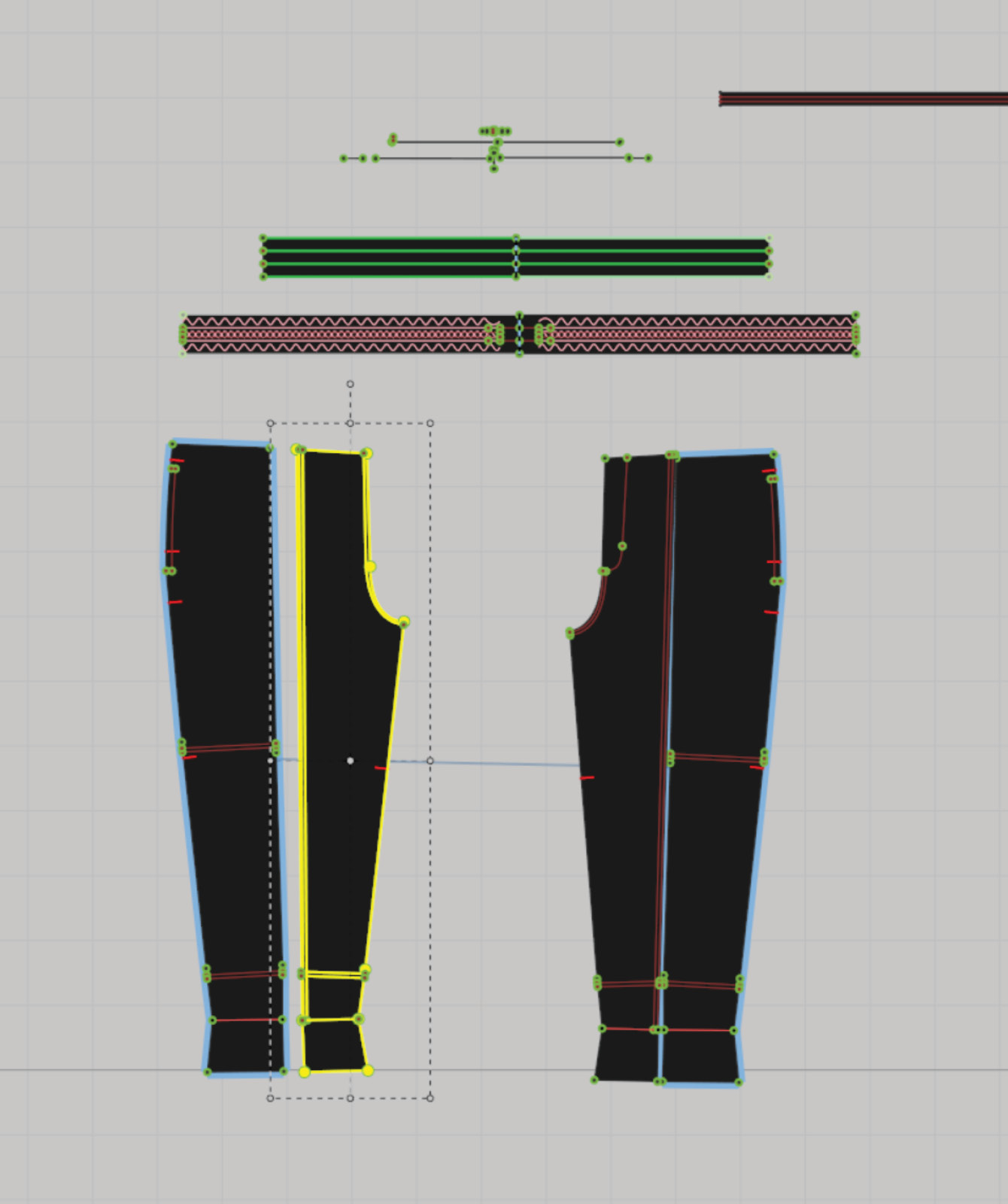

Fashion has ever been evolving, and with it – the technology that surrounds it. JAG has implemented a 3D fashion design technology into our manufacturing process that has cut our sampling costs by half. This technology allows for digital pattern making to happen on 3D garment images, further allowing our designers to innovate both time pressures and costs.

This design process allows for more sustainable manufacturing that minimises sample wastage and transit emission, while also allowing us to optimise the way garments fit on virtual avatars to deliver a better finished product to our website.

To further explain this process, we sat down with one of our digital software design technicians working as part of our design team, Annie.

TELL US ABOUT YOURSELF AND YOUR ROLE HERE AT JAG.

Hi my name is Annie Tran and I am the 3D technician for JAG.

What I do is work with the designer and QA tech to bring their designs to life using 3D imagery. We go through three rounds of virtual fittings. In each round we focus on silhouette, fit, design details and styling. When the 3D garment is finalised, we get to play with colours, prints, trims and finishes. 3D sampling allows us to see what we are getting from our suppliers in real time with accurate specifications tailored to our customers' standards. This increases our confidence then to sign off and buy into these styles for the coming seasons.

We don’t just use 3D in the beginning of a collection but all throughout the development stages until the sample comes in. We continue to use it again in our online and social media stories.

I love what I do and it's so exciting to see the love and support from our customers when we drop a new collection.

WHAT DID YOU STUDY + WHAT INTERESTED YOU ABOUT IT?

I studied a bachelors with honours of design in fashion and textiles at the University of Technology Sydney. At UTS I learnt the fundamentals of design, fashion illustration and pattern-making. It was a great environment to explore your identity as a designer and embrace your creative side.

University was a tough couple years with a lot of long hours researching, sourcing, sewing, and meeting deadlines but I had a lot of fun and created a lot of great memories and skills that translated into what I do now.

Why I chose fashion design was influenced by growing up with a seamstress mum as well as my passion to draw and create. I would remember going to my mum’s shop after work to help her seam rip and mend clothing which I found quite therapeutic.

WHERE DID YOU LEARN ABOUT DIGITAL 3D DESIGN AND WHAT DID YOU ENJOY ABOUT IT?

In my honours year I discovered 3D fashion and was lucky enough to have the downtime during COVID to explore this medium. I trained myself through online tutorials and materials and created a 3D collection titled: Anniesaquarium, showcased in an underwater themed game where the player can manoeuvre through the environment to discover and collect all six outfits. It was tough to be self-taught, but that was also one of the things I enjoyed the most.

I really wanted to push my designs, embracing the unlimited possibilities of 3D design, creating things that disobeyed the physics of reality. It was a vital time in my studies which lead me to do what I do at JAG. I’m still discovering new practices and techniques which is one of the facets that I really enjoy with new technologies. There are no set rules and you can unravel things as you go.

WHY DO YOU THINK IT'S IMPORTANT FOR BRANDS TO DEVELOP THIS KIND OF TECHNOLOGY + INNOVATION IN THEIR PROCESSES?

The benefits of this 3D technology also enable far more sustainable design practices due to minimising sample manufacturing wastage and emissions, while also facilitating improved fitting on virtual 3D avatars. Amid cost and time reduction, the main reason for adopting this process is with sustainability in mind, particularly considering JAG was established on responsible design principles.

The benefit of less sampling production has been profound - in terms of fabrics, the sampling process and sample shipping, these factors have been halved. It's a really sensible innovation in so many ways. In the future, we're excited to explore the power of 3D sampling in designing for circularity - better cutting yields, designing out waste, designing for easy upcycling or repair.